Machine overview

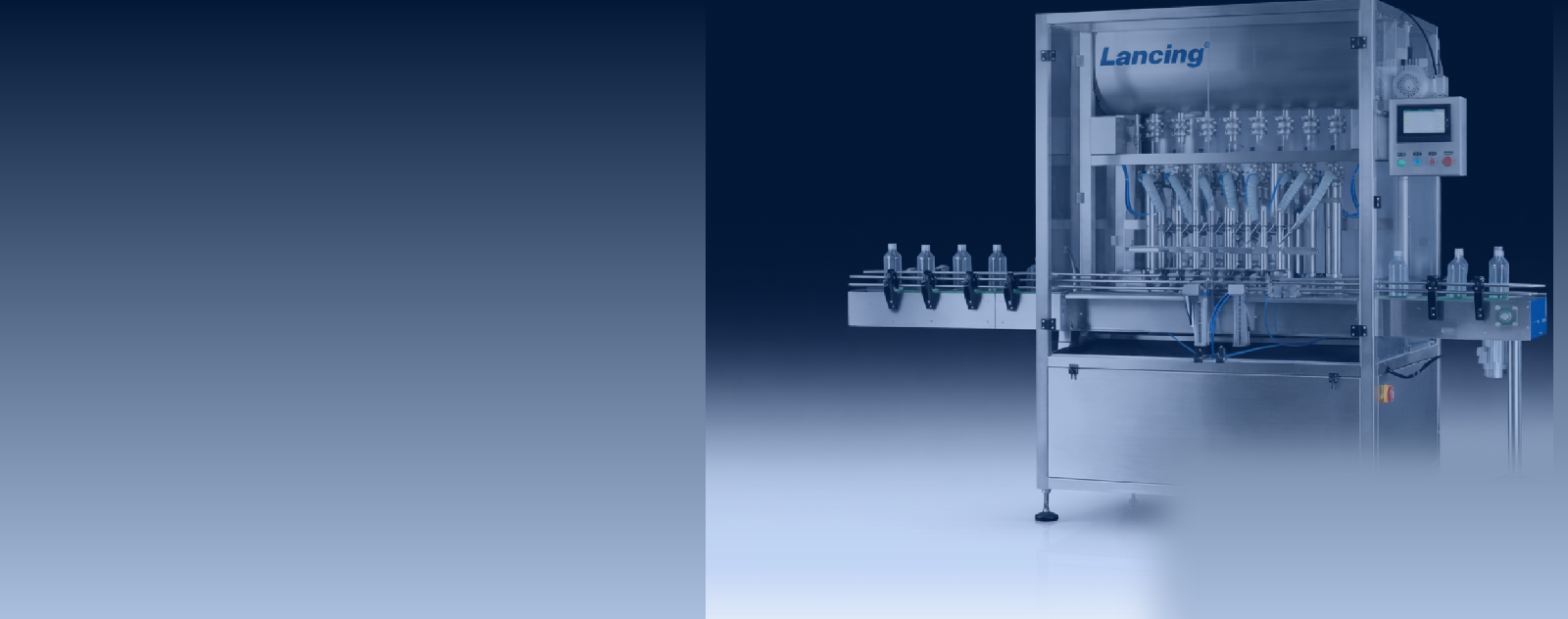

Magnetic Pump Liquid Filling Machine

Machine overview and key points for quotation.

The Lancing UK LU-VTMP80D is a high-precision magnetic pump liquid filling machine designed for clean and efficient production. Equipped with a protective dust cover, it minimizes contamination and ensures product quality. This model supports 1 to 6 customizable filling heads, offering flexible throughput for various container sizes and liquid volumes. Built with durable stainless steel pumps (304/316/316L), it delivers accurate filling from 20ml to 5000ml. Ideal for pharmaceutical, cosmetic, and beverage industries, it can be seamlessly integrated with automatic capping and labeling machines to create a fully automated production line. The PLC control panel shows working parameter clearly,and you can adjust parameter more convenient.Filling speed of each nozzle can be controlled separately.We can customize the operation panel in different kinds of language,if you need this please contact us. Designed with lifting filling nozzle,this is good for filling foamy liquid.It is also equipped with anti-dripping design,this can ensure the product quality and working environment. The 316 stainless steel magnetic pump is good for filling weakly acidic and alkaline like solvent.It fills liquid faster and precisely. Electric eye can detect bottle when they pass through,and send the signal to the system,then the machine will start or stop to work.This can ensure the filling accuracy. The chain conveyor belt is with large weight capacity,it can transport bottles smoothly,help you save production labor and reduce production process.

Throughput

Configurable (confirm during quote)

Target speed depends on product, pack and operator workflow.

Format range

Formats adjustable (bottle/closure dependent)

We’ll configure the machine to your bottle, closure and fill volume.

Utilities

Site utilities to be confirmed

We’ll confirm voltage, air and installation requirements for your site.

Machine gallery

Auto‑scrolling. Hover to pause.

Tip: Reorder images in the product manager — this carousel follows your order.

Specifications

Reference specification table. Final configuration may vary with options and scope.

No specifications listed yet.

CAD / Dimensions

Footprint and dimension reference for planning, guarding and line integration.

No CAD drawing available for this machine.

Site requirements

- Confirm access for delivery, positioning and commissioning.

- Verify utilities and air supply requirements during specification.

- Allow clearance for guarding, maintenance and future upgrades.

Talk to a specialist

We’ll confirm suitability, options, integration, and realistic throughput for your product.

Enquire about this machine

Send a message and we’ll respond with configuration options, pricing guidance and lead times.