Machine overview

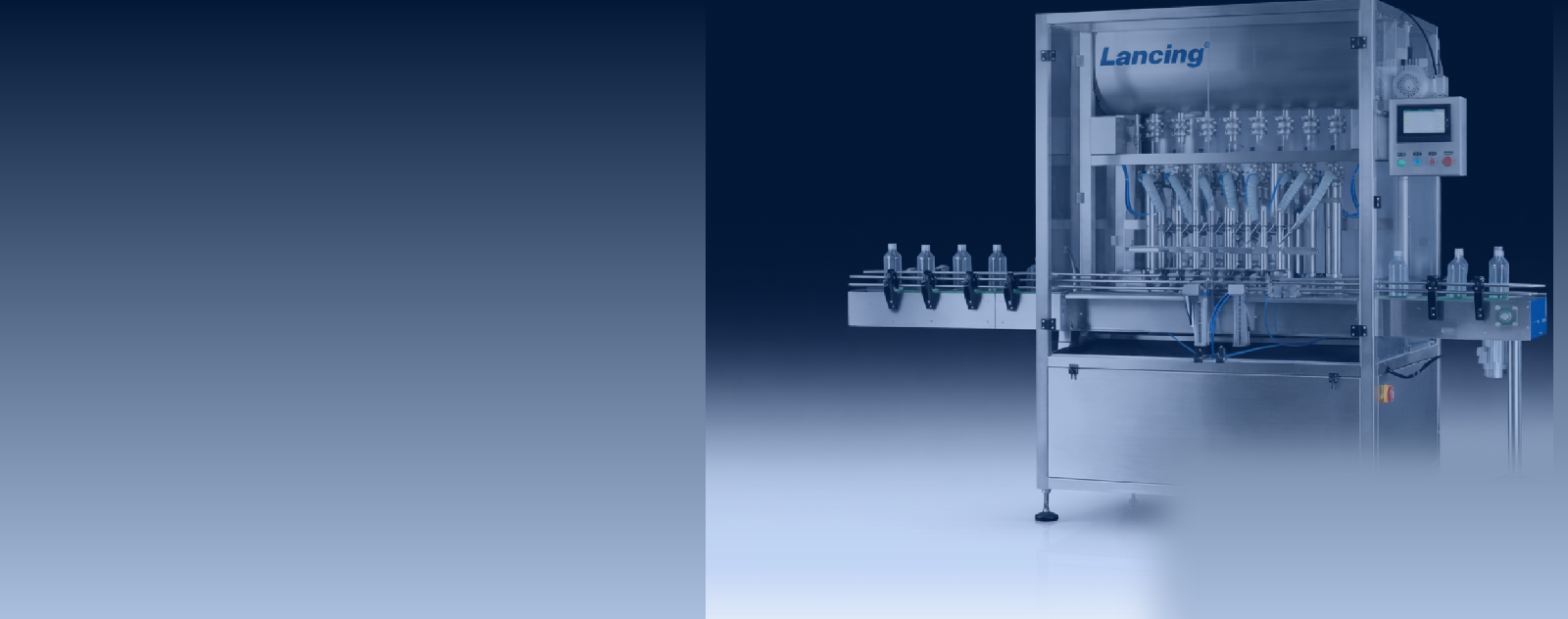

Diaphragm Pump Water Oil Liquid Filling Machine

Machine overview and key points for quotation.

1.This numerical control liquid filling machine is compact and portable. The casing uses stainless steel so it is durable and easy to clean. The machine has a self-prime pump that can suck in the liquid from your container and then output via the nozzle. It can be used to fill many different types of clear thin liquid,including water, olive oil, fuel, drinks, vinegar, milk etc. 2.Liquid suitable: low viscous liquid like water, wine, solutions etc. Liquid unsuitable: very thick liquid (sauce,detergent etc), or liquid containing small particles. ATTENTION 1. Different liquid needs to choose different material of tube. The tube provided by us is silicone tube. 2.We will test all of the filling machine before send out , so it’s normal that the machine pump and tube with water inside when you receive it.

Throughput

Configurable (confirm during quote)

Target speed depends on product, pack and operator workflow.

Format range

≤500ml Maximum Flow Rate: 3.1L/min (water)

We’ll configure the machine to your bottle, closure and fill volume.

Utilities

AC 220V / 110V, 50/60Hz, 40W

We’ll confirm voltage, air and installation requirements for your site.

Machine gallery

Auto‑scrolling. Hover to pause.

Tip: Reorder images in the product manager — this carousel follows your order.

Specifications

Reference specification table. Final configuration may vary with options and scope.

| Parameter | Value |

|---|---|

| Model | LU-GFK160 |

| Voltage Power | AC 220V / 110V, 50/60Hz, 40W |

| Recommended Filling Range | ≤500ml Maximum Flow Rate: 3.1L/min (water) |

| Filling Nozzle Diameter | Φ8mm |

| Maximum Suction Distance | 2m Filling Accuracy: ± ≤0.5% |

| Anti-Dripping Function | Included |

| Power-Off Memory Function | Included |

| Compatible Tubing | Model 17# (Inner Diameter: 6.4mm, Wall Thickness: 1.6mm) |

| Packing Size | 325 × 275 × 180 mm |

| Gross Weight | 2.75kg |

CAD / Dimensions

Footprint and dimension reference for planning, guarding and line integration.

No CAD drawing available for this machine.

Site requirements

- Confirm access for delivery, positioning and commissioning.

- Verify utilities and air supply requirements during specification.

- Allow clearance for guarding, maintenance and future upgrades.

Talk to a specialist

We’ll confirm suitability, options, integration, and realistic throughput for your product.

Enquire about this machine

Send a message and we’ll respond with configuration options, pricing guidance and lead times.