Machine overview

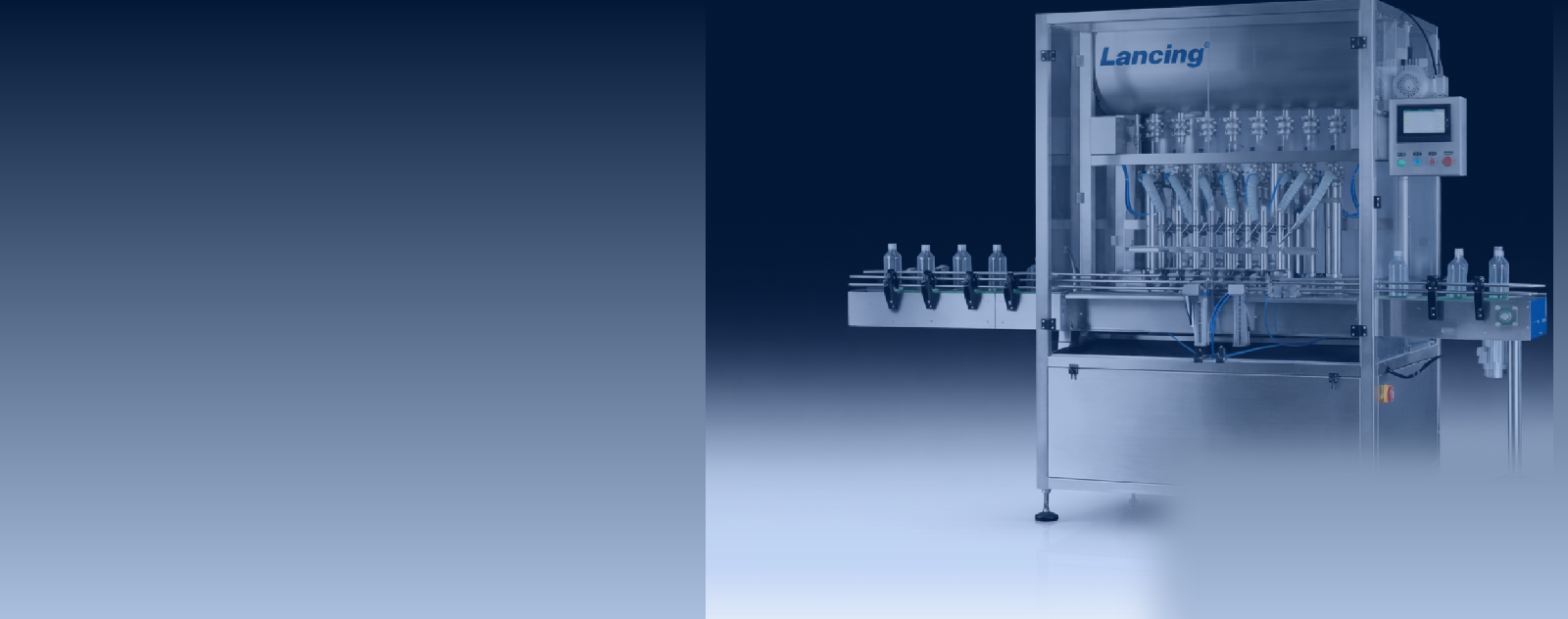

Pneumatic Vacuum Liquid Filling Machine

Machine overview and key points for quotation.

The vacuum liquid filling machine is a pure pneumatic equipment and requires no electricity,it can prevent the fragrance from spreading,this is especially good for perfume filling. The GZ-G4000 uses the vacuum constant liquid level filling principle, regardless of whether the bottle volume is the same, the filling liquid level will remain the same. Application This machine is mainly used for filling small doses of liquid materials such as toilet water, perfume, skin care water, eye drops, oral liquid, sesame oil, fruit juice drinks, carbonated drinks, mineral water, purified water, alcohol, battery liquid, detergent, etc. The main power of this machine is air source, customers need to buy the air compressor separately.

Throughput

50 Bottles / Minute

Target speed depends on product, pack and operator workflow.

Format range

Max applicable viscosity is 20Cps (static viscosity)

We’ll configure the machine to your bottle, closure and fill volume.

Utilities

0.5–0.8 MPa

We’ll confirm voltage, air and installation requirements for your site.

Machine gallery

Auto‑scrolling. Hover to pause.

Tip: Reorder images in the product manager — this carousel follows your order.

Specifications

Reference specification table. Final configuration may vary with options and scope.

| Parameter | Value |

|---|---|

| Parameter | 2 Heads |

| Air Pressure | 0.5–0.8 MPa |

| Liquid Level Accuracy | ±1 mm |

| Viscosity Range | Max applicable viscosity is 20Cps (static viscosity) |

| Working Speed | 50 Bottles / Minute |

| Bottle Height | ≤250 mm |

| Bottle Opening Size | ≤φ4.5mm–φ28mm |

| Adjustable Liquid Level (from bottle mouth) | <27 mm |

| Dimensions (excluding storage bottles) | 400 × 320 × 1400 mm |

| Pumping Rate | 5.5 L/s |

CAD / Dimensions

Footprint and dimension reference for planning, guarding and line integration.

No CAD drawing available for this machine.

Site requirements

- Confirm access for delivery, positioning and commissioning.

- Verify utilities and air supply requirements during specification.

- Allow clearance for guarding, maintenance and future upgrades.

Talk to a specialist

We’ll confirm suitability, options, integration, and realistic throughput for your product.

Enquire about this machine

Send a message and we’ll respond with configuration options, pricing guidance and lead times.