Machine overview

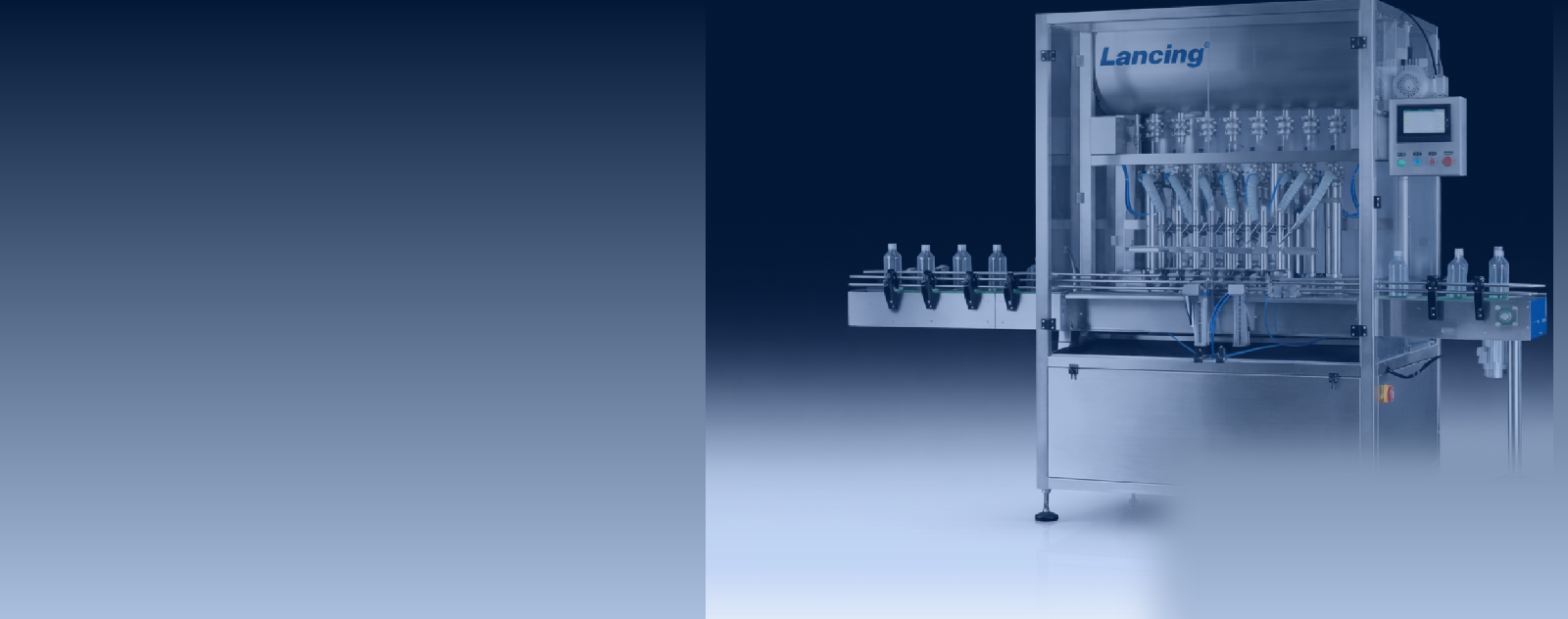

ZS-YTCR1A Corrosive Liquid Filling Machine

Machine overview and key points for quotation.

The Lancing UK LU-YTCR1A is a single-head automatic filling machine specifically designed for corrosive chemical liquids. Constructed from high-grade PP material, it offers excellent resistance to chemical wear and ensures long-term durability. The machine operates via a conveyor system with pneumatic clamping and filling mechanisms, delivering precise, hands-free filling for bottles ranging from 10ml to 5L. With a production capacity of up to 1500 bottles per hour and ±0.3% filling accuracy, it’s ideal for chemical plants, industrial cleaning product manufacturers, and other hazardous liquid applications. This system enhances safety, reduces labor, and ensures consistent output. LU-YTCR1A Automatic Filling Machine – Technical Specifications Parameter Specification Model LU-YTCR1A Power Supply AC 220V / 380V Power Consumption 2.4 kW (50–60Hz) Applicable Bottleneck ≥ Φ30mm Bottle Types Supported 10ml–5L round, oblate, square, and oblate square bottles Working Air Pressure 0.6–0.8 Mpa Filling Accuracy ±0.3% (based on 500ml volume) Production Capacity 1500 bottles/hour (based on 500ml) Machine Dimensions 2000 × 1100 × 1800 mm (customizable based on actual packaging size) Equipment Weight Approx. 300 kg

Throughput

Configurable (confirm during quote)

Target speed depends on product, pack and operator workflow.

Format range

Formats adjustable (bottle/closure dependent)

We’ll configure the machine to your bottle, closure and fill volume.

Utilities

Site utilities to be confirmed

We’ll confirm voltage, air and installation requirements for your site.

Machine gallery

Auto‑scrolling. Hover to pause.

Tip: Reorder images in the product manager — this carousel follows your order.

Specifications

Reference specification table. Final configuration may vary with options and scope.

No specifications listed yet.

CAD / Dimensions

Footprint and dimension reference for planning, guarding and line integration.

No CAD drawing available for this machine.

Site requirements

- Confirm access for delivery, positioning and commissioning.

- Verify utilities and air supply requirements during specification.

- Allow clearance for guarding, maintenance and future upgrades.

Talk to a specialist

We’ll confirm suitability, options, integration, and realistic throughput for your product.

Enquire about this machine

Send a message and we’ll respond with configuration options, pricing guidance and lead times.