Machine overview

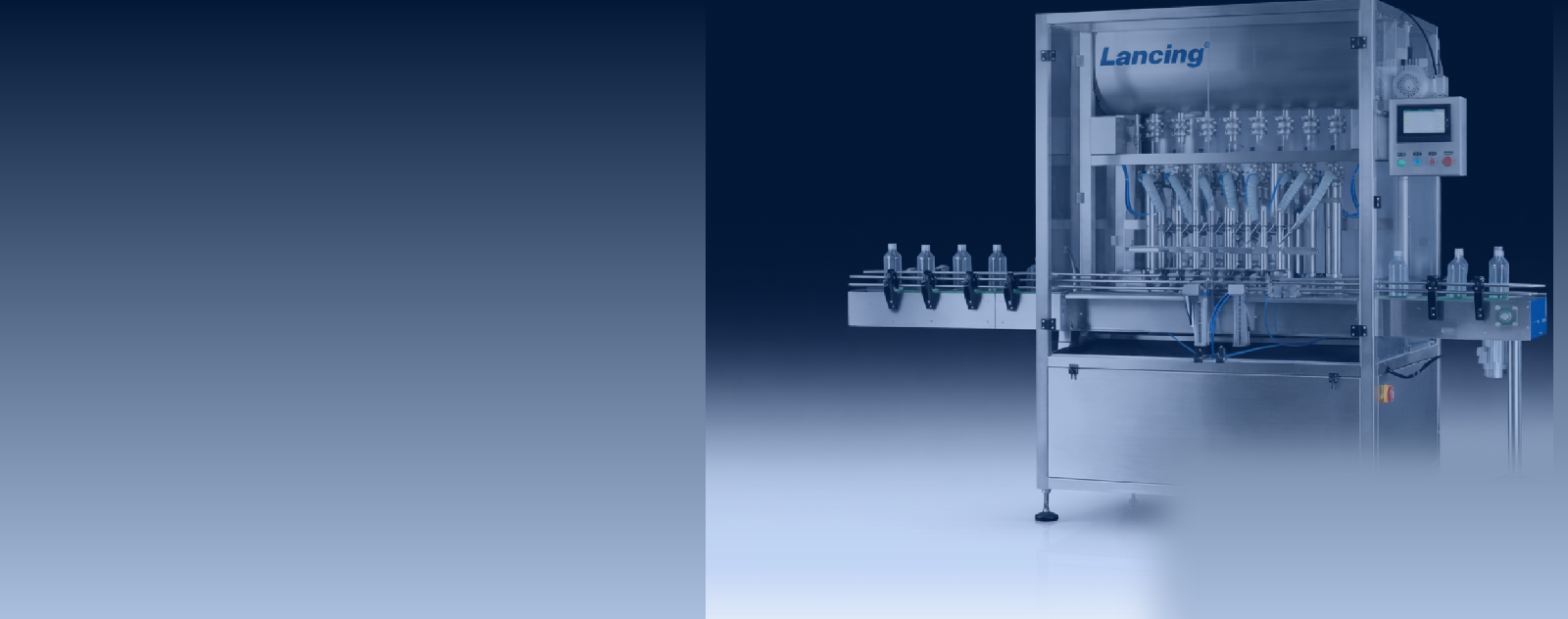

ZS-YTPP2 Dual Nozzle Peristaltic Pump Liquid Filling Machine

Machine overview and key points for quotation.

The Lancing UK LU-YTPP2 is a high-efficiency liquid filling machine equipped with dual peristaltic pumps, designed to boost productivity while maintaining precision. Its contamination-free design ensures that liquid flows only through the replaceable tubing, making it ideal for hygienic applications. Widely used in food, cosmetics, and daily chemical industries, this machine offers accurate filling, anti-drip protection, and memory recovery after power loss—perfect for small-scale production and lab environments. Lancing UK LU-YTPP2 Dual Nozzle Peristaltic Pump Liquid Filling Machine Specifications Parameter Details Machine Model LU-YTPP2 Voltage 220V / 110V, 50–60Hz Power Approx. 100W Pump Type Peristaltic Pump Filling Range 3–2400 ml Flow Rate 2.2 L/min × 2 (based on water) Filling Accuracy ≤ ±1% Filling Head Diameter Outer Diameter 6 mm Anti-Dripping Function Available Memory Function (Power Loss) Available Machine Dimensions Approx. 505 × 310 × 260 mm (L × W × H) Machine Weight Approx. 19 kg Package Dimensions Approx. 615 × 435 × 320 mm (L × W × H) Package Weight Approx. 26 kg

Throughput

Configurable (confirm during quote)

Target speed depends on product, pack and operator workflow.

Format range

Formats adjustable (bottle/closure dependent)

We’ll configure the machine to your bottle, closure and fill volume.

Utilities

Site utilities to be confirmed

We’ll confirm voltage, air and installation requirements for your site.

Machine gallery

Auto‑scrolling. Hover to pause.

Tip: Reorder images in the product manager — this carousel follows your order.

Specifications

Reference specification table. Final configuration may vary with options and scope.

No specifications listed yet.

CAD / Dimensions

Footprint and dimension reference for planning, guarding and line integration.

No CAD drawing available for this machine.

Site requirements

- Confirm access for delivery, positioning and commissioning.

- Verify utilities and air supply requirements during specification.

- Allow clearance for guarding, maintenance and future upgrades.

Talk to a specialist

We’ll confirm suitability, options, integration, and realistic throughput for your product.

Enquire about this machine

Send a message and we’ll respond with configuration options, pricing guidance and lead times.