Machine overview

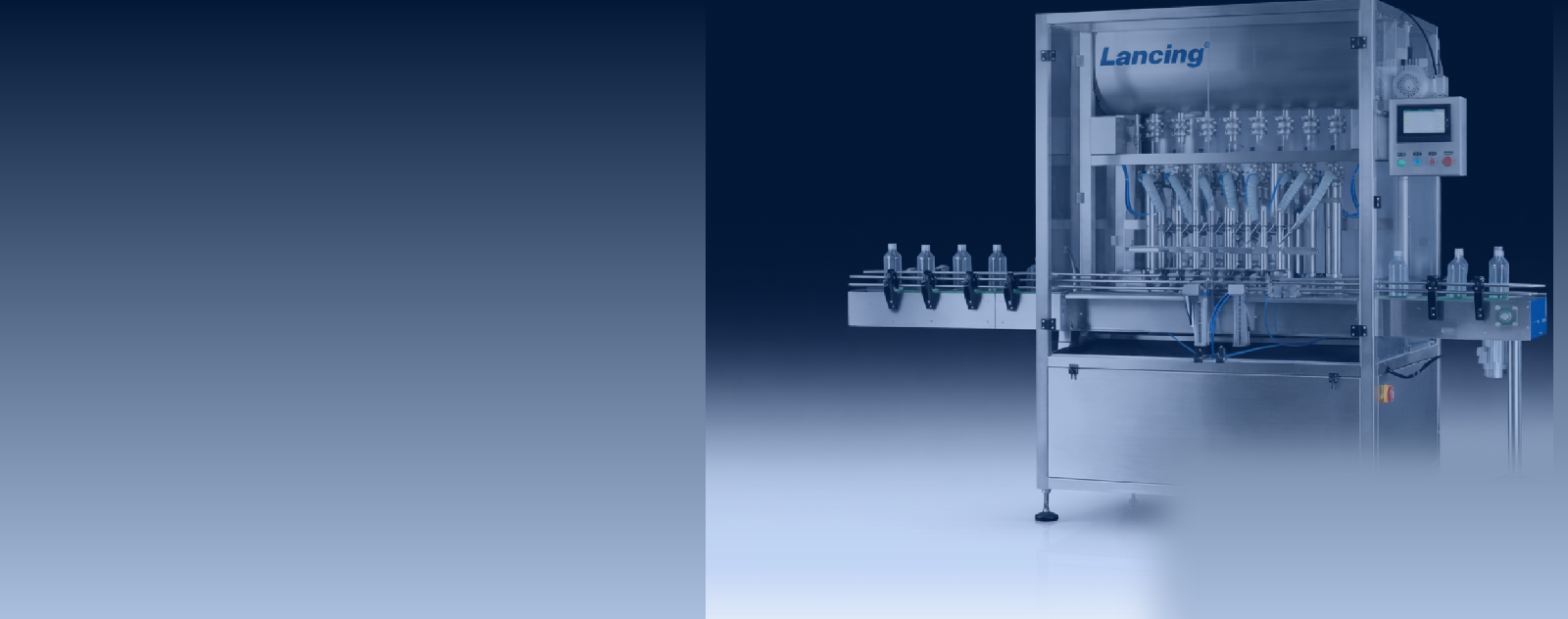

ZS-YTZL4A 4-Head Vacuum Liquid Filling Machine

Machine overview and key points for quotation.

The Lancing UK LU-YTZL4A is a high-precision vacuum liquid filling machine equipped with four pneumatic filling nozzles featuring back-suction and liquid level control. Designed for low-viscosity liquids such as perfume, water, and juice, it ensures clean, accurate filling without overflow. The PLC touchscreen panel allows easy parameter setup with customizable language options. Integrated electric eye detection and a durable chain conveyor belt enhance automation and efficiency. Ideal for cosmetic and beverage industries, this machine can be seamlessly integrated into a full production line with automatic capping and labeling systems.

Throughput

Configurable (confirm during quote)

Target speed depends on product, pack and operator workflow.

Format range

Formats adjustable (bottle/closure dependent)

We’ll configure the machine to your bottle, closure and fill volume.

Utilities

Site utilities to be confirmed

We’ll confirm voltage, air and installation requirements for your site.

Machine gallery

Auto‑scrolling. Hover to pause.

Tip: Reorder images in the product manager — this carousel follows your order.

Specifications

Reference specification table. Final configuration may vary with options and scope.

| Parameter | Value |

|---|---|

| Machine Model | LU-VTZL4A Filling Head :4 Head Air Pressure :0.5–0.8 MPa Liquid Level Accuracy :±1 mm Viscosity Range :The maximum applicable viscosity is 20Cps (static viscosity) Working Speed :20–40 bottles/min Bottle Height :≤250 mm Bottle Opening Size :Φ8–28 mm Adjustable Liquid Level (from bottle mouth) :15–50 mm Pumping Rate :5.5 L/min Machine Size :About 20208001410 mm Package Size :About 133021051670 mm Package Weight :About 335 kg |

CAD / Dimensions

Footprint and dimension reference for planning, guarding and line integration.

No CAD drawing available for this machine.

Site requirements

- Confirm access for delivery, positioning and commissioning.

- Verify utilities and air supply requirements during specification.

- Allow clearance for guarding, maintenance and future upgrades.

Talk to a specialist

We’ll confirm suitability, options, integration, and realistic throughput for your product.

Enquire about this machine

Send a message and we’ll respond with configuration options, pricing guidance and lead times.